Magnetic polishing machine is an efficient and convenient surface treatment equipment, which is widely used in polishing, deburring, cleaning and other fields of various Metals, plastics, glass and other materials. For surface defects such as knife marks and scratches, magnetic polishing machine has the advantage of solving them in one go. The following is a detailed description of the characteristics and operation process of magnetic polishing machine in dealing with knife marks and scratches.

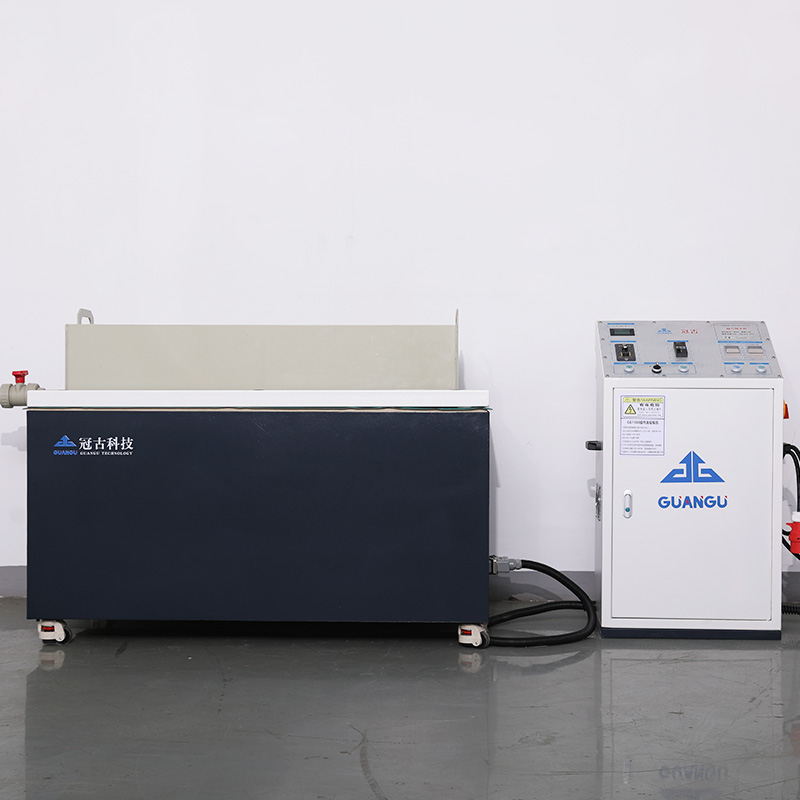

Magnetic polishing machine adopts the principle of electromagnetic field, adsorbs abrasives through magnetic field, makes abrasives move at high speed on the surface of workpiece, and produces grinding and polishing effect. The equipment is mainly composed of controller, polishing tank, magnetic pole, abrasive and other parts. When working, put the workpiece into the polishing tank, add abrasives and water, start the equipment, and the abrasives polish the workpiece in all directions under the action of magnetic field.

Knife marks and scratches can be solved in one go: magnetic polishing machine adopts all-round polishing method, which can remove knife marks, scratches and other defects on the surface of workpiece at one time and improve surface finish.

Fast polishing speed: Compared with traditional polishing methods, magnetic polishing machines have higher efficiency and greatly shorten the production cycle.

Easy operation: The magnetic polishing machine adopts one-button operation, and the operator does not need professional skills and can easily get started.

Wide range of applications: The magnetic polishing machine is suitable for workpieces of various shapes and sizes, especially for polishing workpieces with complex shapes.

Safety and environmental protection: During the operation of the equipment, the abrasive is separated from the workpiece, reducing dust pollution and ensuring the health of the operator.

Preparation: Install the magnetic polishing machine firmly and turn on the power. According to the material of the workpiece and the polishing requirements, select the appropriate abrasive and polishing liquid.

Place the workpiece: Put the workpiece to be polished into the polishing tank, and pay attention to keep a certain distance between the workpieces to avoid collision with each other.

Add abrasive and polishing liquid: Add an appropriate amount of abrasive and polishing liquid according to the number of workpieces and the capacity of the polishing tank. The ratio of abrasive to polishing liquid is generally 1:1.

Start the equipment: Turn on the magnetic polishing machine and adjust the polishing time. During the operation of the equipment, the abrasive polishes the workpiece in all directions under the action of the magnetic field.

Polishing is completed: After the set time is over, turn off the equipment and take out the workpiece. At this time, the knife scratches on the surface of the workpiece have been removed and the finish has been improved.

Cleaning the site: Filter and recycle the abrasive and polishing liquid in the polishing tank, and clean the environment around the equipment.

During the polishing process, ensure that the workpiece is fully in contact with the abrasive to improve the polishing effect.

Regularly check the abrasive wear and replace the abrasive in time to ensure the polishing effect.

During the operation, pay attention to safety to prevent accidents such as electric shock and burns.

In short, the magnetic polishing machine has significant advantages in dealing with knife scratches, which provides a strong guarantee for enterprises to improve production efficiency and reduce costs. With the continuous advancement of technology, magnetic polishing machines will play an important role in more fields.